Introduction

In recent years, ostomy care has seen a seismic shift towards improving patient quality of life. From a product design point of view, this means manufacturing ostomy bags that prioritize aesthetics, comfort and enhanced functionality. This shift is not just a trend; it’s a reflection of the growing demand from consumers for products that not only serve their medical needs but also enrich their lives and seamlessly blend into their daily routines without compromising confidence or self-expression.

In this blog, we delve into the evolving landscape of ostomy bag design, including the considerations from a manufacturing point of view as well as cost and regulatory implications.

Key Takeaways:

- Innovations in the Market: Examples of new product designs that reflect the growing trend towards patient-centric ostomy bags.

- Material Selection: A closer look at the materials to consider for manufacturing patient-centric ostomy bags.

- Components: Rethinking the components of ostomy bags to enhance comfort and functionality.

- Manufacturing Considerations: Important factors to consider and the benefits of working with partners that are 100% focused on medical devices.

- The Road Ahead: Why PolarSeal is the preferred partner for a growing number of ostomy brands.

Innovations in the Market

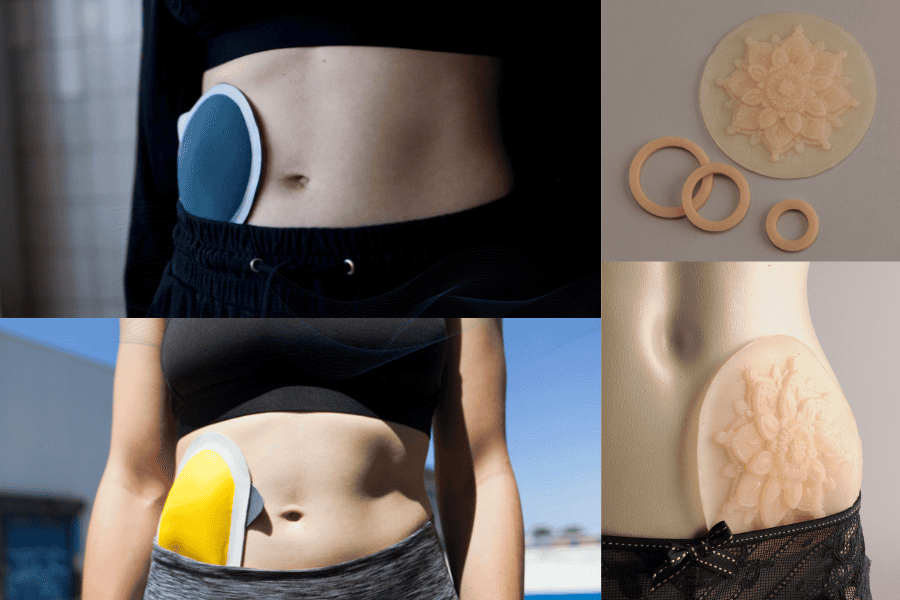

The market is already starting to see updates to ostomy bag design with innovations like “Guts” by Teddy Schuyers and “Intimate Moments” by Stephanie Monty breaking through with great commercial success. These design updates demonstrate a shift towards patient-centric ostomy bags. Schuyers’ “Guts” offers a sleek, minimalist design made of lightweight materials, providing a discreet alternative to traditional bulky bags, perfect for blending into daily activities including sport and even swimming.

Monty’s “Intimate Moments” collection caters to moments of romance and intimacy by making ostomy bags a bit easier on the eye with skin-colored silicone covers and a choice of patterns, enabling ostomates to embrace their bodies confidently. These collections prioritize both functionality and aesthetics, enriching the lives of ostomates with an inclusive approach to ostomy care.

Material Selection

From a manufacturing point of view, the shift towards patient-centric ostomy bags necessitates careful selection of materials that prioritize aesthetics, discretion, breathability and comfort. Traditional ostomy bags are making way for lightweight, hypoallergenic fabrics that mimic the skin’s natural color, texture and flexibility.

Some good materials for patient-centric ostomy bags include:

- Thermoplastic films: Lightweight yet durable materials like thermoplastic polyurethane (TPU) and thermoplastic elastomers (TPE) are being used to create sleek, minimalist ostomy bags that conform to the body’s curves.

- Tyvek polyethylene coatings: Providing a discreet, paper-like appearance, Tyvek coatings offer breathability and moisture resistance.

- Silicone covers: Flexible silicone covers can be color-matched to the patient’s skin tone, offering a seamless and natural-looking fit, particularly for intimate situations.

- Patterned silicone: Beyond solid colors, some designs feature embossed or patterned silicone covers, adding a decorative element while maintaining discretion.

- PVC-coated fabrics: For active wear, PVC-coated fabrics provide durability and moisture resistance, allowing for greater freedom of movement during sports or physical activities.

- Soft, stretch fabrics: Smaller, discreet ostomy bags are being crafted from soft, stretchy materials that move with the body, ensuring comfort and discretion during intimate moments.

- Odor-resistant, antimicrobial materials: Increasing in popularity are materials with odor-resistant and antimicrobial properties, helping to reduce embarrassment and lower the risk of infections associated with ostomy bags.

By incorporating these innovative materials, ostomy bag manufacturers are not only enhancing aesthetics but also addressing crucial aspects like breathability, flexibility, user comfort, odor control and infection prevention, ultimately improving the overall quality of life for ostomates.

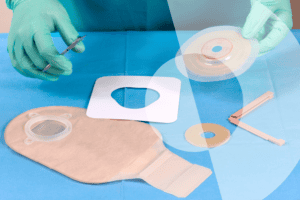

Components

In addition to the pursuit of better aesthetics, there is a growing demand for enhanced functionality and wearer comfort. This means rethinking how ostomy components are designed. Key advancements in this area include:

- Flexible, Molded Components: Ostomy bags now incorporate flexible and molded components such as flanges and pouches, allowing for a closer conformity to the body’s contours. This minimizes bulkiness and improves wearer comfort by reducing the risk of irritation and discomfort caused by friction against the skin.

- Ergonomic Closures: Modern ostomy bags feature ergonomic closures, including magnetic or hook & loop options, which ensure secure sealing while facilitating easy bag changing. These closures not only enhance the overall discretion of the bag but also prioritize ease of use, empowering ostomy patients to manage their condition with confidence and convenience.

Manufacturing Considerations

The shift towards patient-centric ostomy bags necessitates careful manufacturing considerations that underscore the need for an expert manufacturing partner dedicated to the medical device industry. Material and component selection play a critical role in achieving the desired balance between product quality, cost-effectiveness and lead times. From hypoallergenic fabrics to antimicrobial agents, the choice of materials must meet stringent regulatory standards while addressing the unique requirements of ostomy patients. Additionally, the integration of flexible, molded components and ergonomic closures demands precision engineering and expertise in product design and R&D.

A manufacturing partner that is 100% focused on the medical device industry brings invaluable insights and capabilities to the table, guiding the selection of the best materials and components to optimize product performance and patient satisfaction. By leveraging this expertise, ostomy and medical device brands can streamline manufacturing, mitigate risks and ensure compliance with regulatory requirements. Ultimately, partnering with a manufacturing partner that is 100% focused on medical devices is essential for delivering high-quality ostomy products that meet the growing demands of consumers.

The Road Ahead

As the evolution of ostomy bag design continues to prioritize improving patient quality of life, it’s crucial for medical device brands to stay ahead of the competition. By partnering with PolarSeal, a company fully dedicated to the medical device industry, brands gain a significant advantage. PolarSeal offers a turnkey solution for companies manufacturing ostomy bags, allowing brands to focus on what they do best while PolarSeal handles every aspect of the manufacturing process.

Read More from PolarSeal

Four Innovations Revolutionising Wound Care

In this blog, we look at the latest innovations in wound care focusing on the benefits to consumers and important manufacturing considerations to be aware of.

From Material to Wearable Reality: PolarSeal®’s CGM Patch Development Explored

The advent of Continuous Glucose Monitoring (CGM) patches has revolutionised diabetes management, offering patients a non-intrusive, real-time window into their glucose levels. This technology is

How can AI advance Cancer research?

Globally, it’s estimated that over 19 million people are diagnosed with cancer each year, and these statistics continue to rise with 1 in 2 of