Diagnostic components - tight tolerance converting

Manufacturing processes for accurate diagnostic testing devices

Reliable and extremely accurate membrane-based diagnostic testing is used by millions of patients globally daily.

Material converting for diagnostics

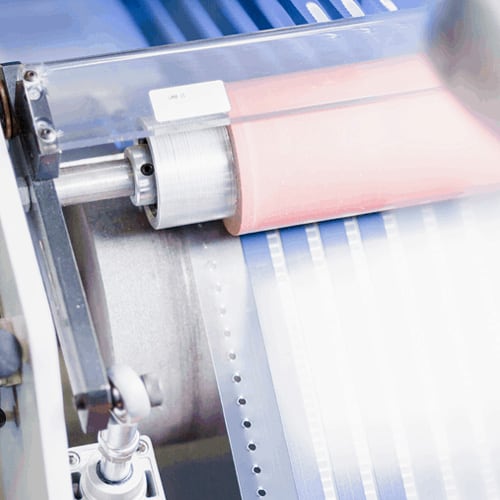

The development of accurate in-home and over-the-counter diagnostic test products for a wide range of healthcare issues has driven intense development of multi-layer laminate construction of specialist adhesive coated films and space tape lamination. PolarSeal® has been actively involved in this fast-growing market sector from the start and now plays a major role in the development and manufacture of new diagnostic test strips.

Applications overview

PolarSeal® is fully qualified in this advanced technical field and can offer great flexibility in terms of the options possible in respect of the design and production specifications of these specialist products which may include:

- Membrane-based diagnostic requirements – non-migratory inert adhesive systems for compatibility with assay-type diagnostic testing devices

- Capillary flow – various thickness materials used to facilitate volume requirements by utilising varying sized channels to regulate the amount of specimen being tested

- Hydrophilic characteristics – to customize the flow of specimen by the selection of the various coatings and adhesives available, by the control of surface tension required to reduce the test time and sample size through offering enhanced wicking

- Versatile processing capability – conformable and ease of die-cutting

- Matching the surface energy of biological fluids

- Tape construction – single coated, double-coated, or transfer film

- Diagnostic test strip

Case study

The rising demand of accurate in-home and over-the-counter diagnostic test products for a wide range of healthcare issues is driving intense innovation within this field. The nature of these products demands incredibly tight tolerances within manufacturing, and this poses many challenges to a contract medical manufacturer. This was the case with a client who approached us with this exact need and required a solution to supply to a demanding market.