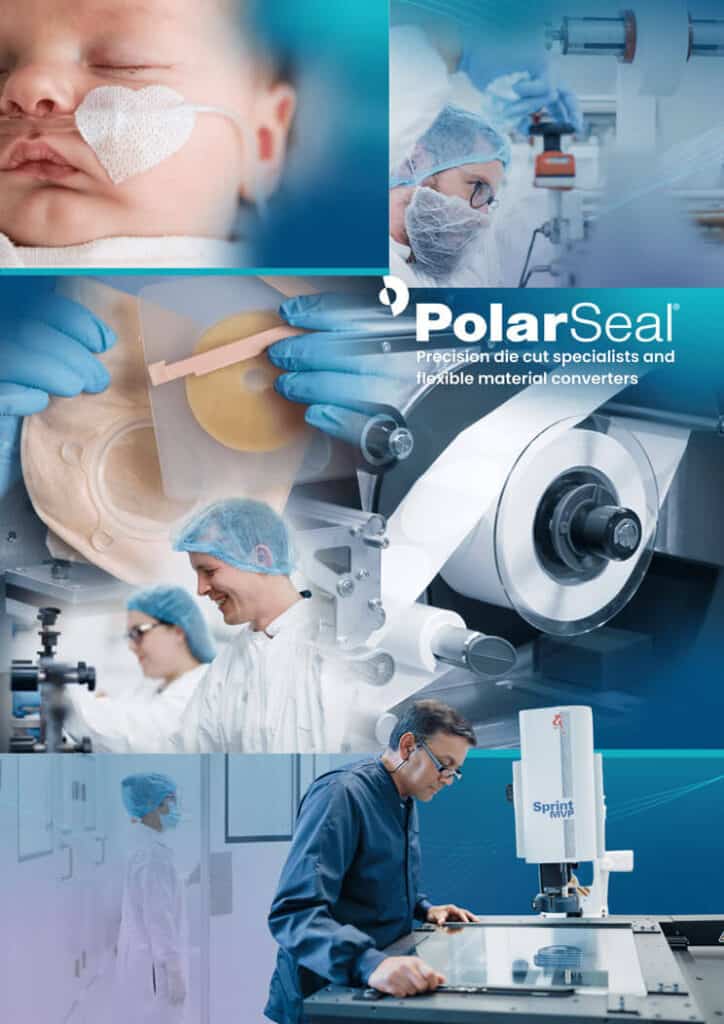

Adhesive tape converter focused on medical material and contract manufacturing

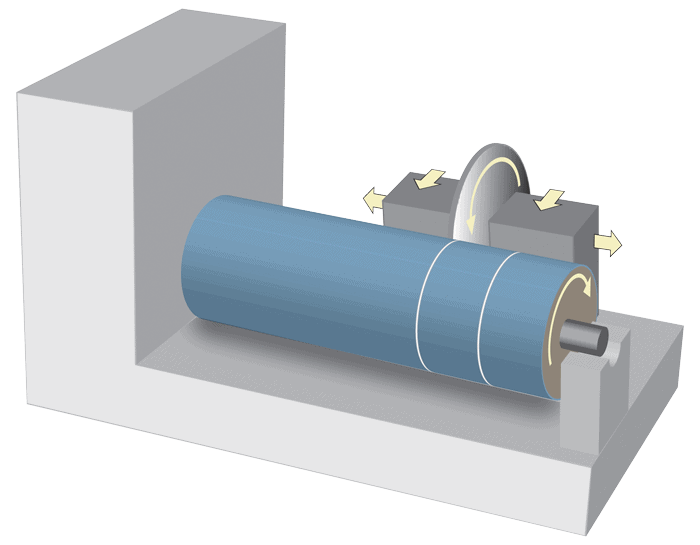

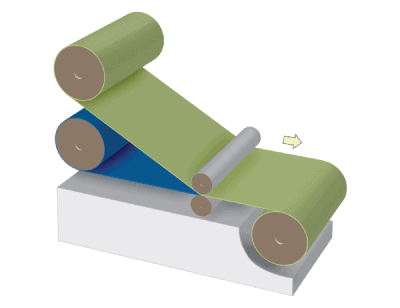

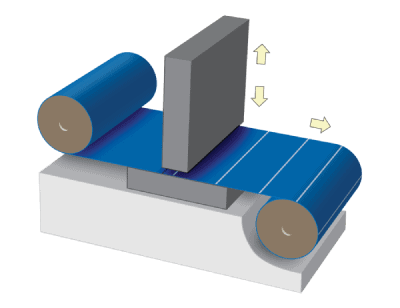

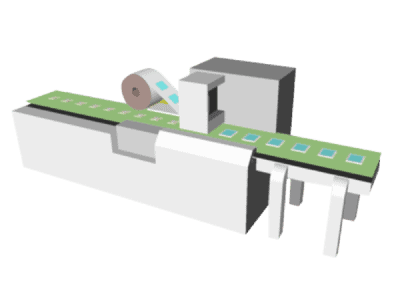

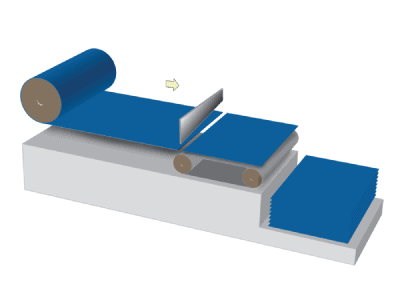

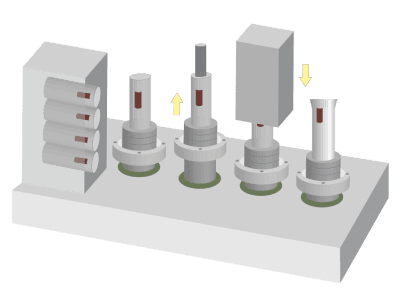

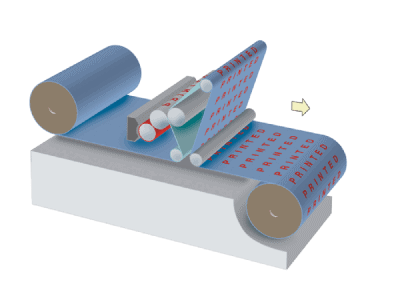

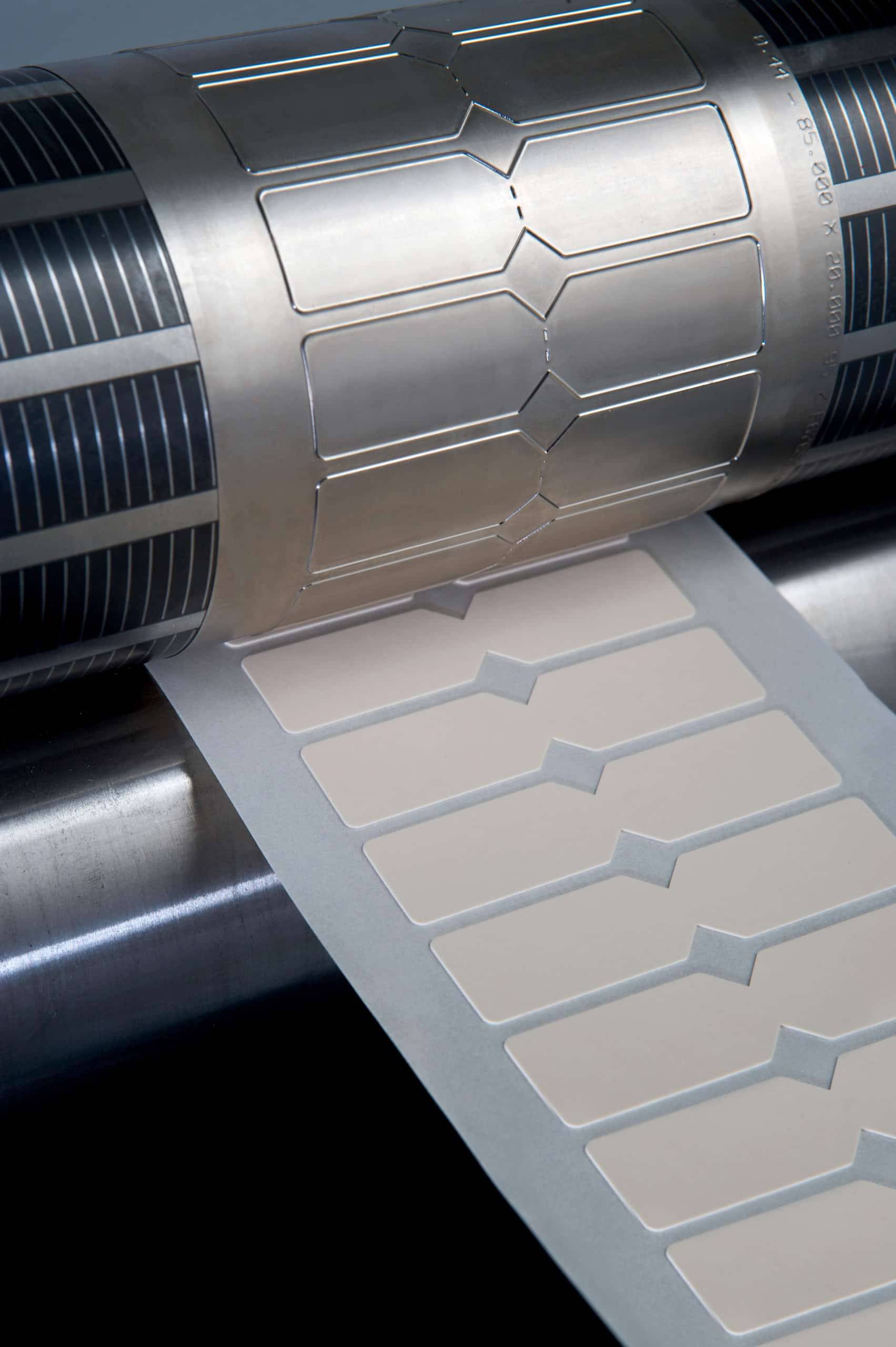

Converting capabilities

Getting to

know us

PolarSeal® was established as a medical material converter and continues to be at the forefront of the healthcare contract manufacturing industry providing adhesive solutions.

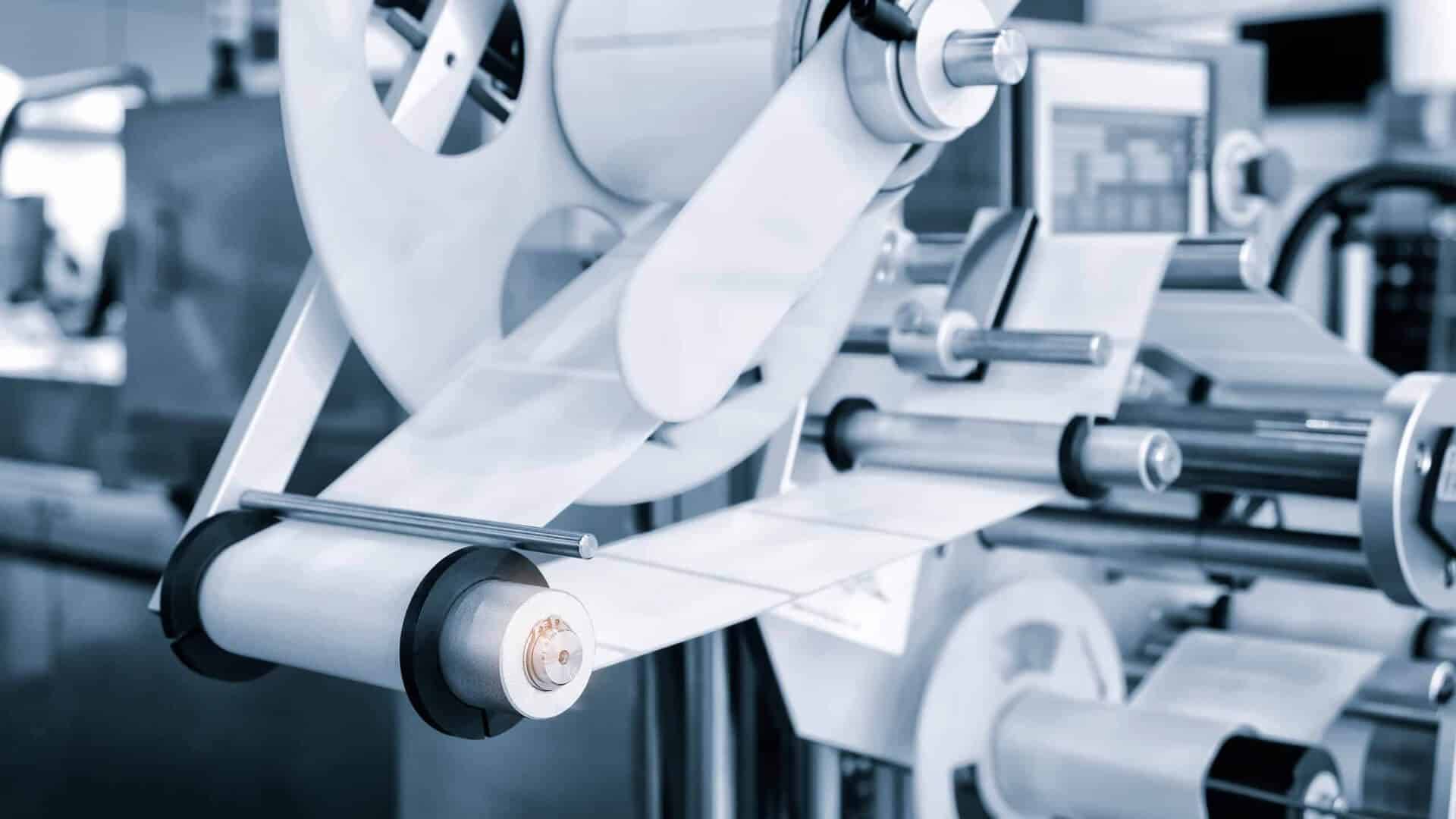

PolarSeal delivers turnkey solutions for medical device companies worldwide, utilizing our flexible material converting and tape conversion expertise using our sophisticated production lines, machinery, and revolutionary & bespoke manufacturing processes.

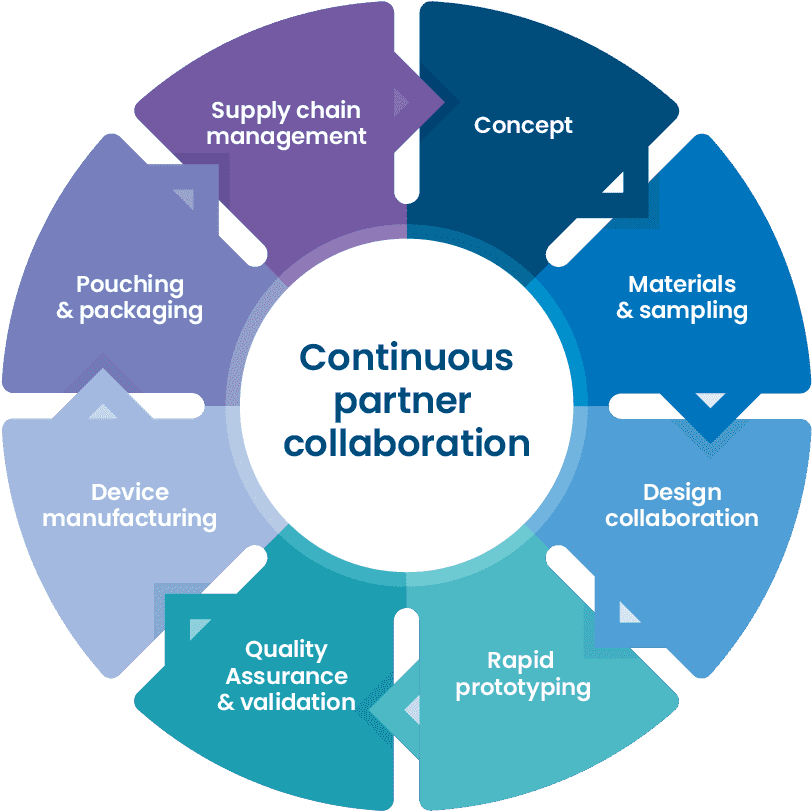

Continuous partner collaboration

From the initial concept through to supply chain management, PolarSeal® provides a solution to fulfil your entire project expectations from beggining to end.

Customers can enter the cycle at any point and let PolarSeal manage the project going forward with clear, concise, and continuous communication.

Our converting experts, R&D professionals, Quality Assurance teams and designated project managers are here for you.

100% dedicated to medical with international multi-site manufacturing

With international warehousing and production facilities equipped with the latest converting technology and consistent supply chains, we can meet high-volume manufacturing demands on time and in full. PolarSeal®’s all-in-one solution simplifies your logistics processes, reduces carbon footprint, and creates clear and concise communication channels.

PolarSeal® delivers customized and bespoke adhesive components around the world, backed by extensive medical-grade material knowledge.

PolarSeal® is an FDA Registered and Audited company upholding ISO 13485 quality standards operating with ISO 7 Cleanrooms to 14644-1.

CONVERTING NEWS

Latest posts

PolarSeal® brings you a variety of blogs and news stories to keep you updated with not only our movements but also industry news.

Microplate Sealing Films: Selecting the Right Materials and Design

Microplates are essential in laboratory research, allowing for precise tests and analyses that demand meticulous sample handling. An important aspect to ensuring the accuracy of these tests is selecting the right sealing film, which can significantly affect the success of an experiment. Sealing films serve several functions, including preventing evaporation, contamination control and preserving sample integrity. Given the critical nature of these functions, it is important to have a deep understanding of the various types of sealing films available.

Exploring Different Types of Medical Adhesives

Selecting the right adhesive for your medical device is critical for both patient comfort and the profitability of your product. With various types of medical-grade adhesives available, it’s important to understand the unique properties of each to design devices that perform optimally and ensure patient satisfaction. In this blog, we review the different medical-grade adhesives, highlighting the important characteristics and primary use cases of each.