Advanced Material Converting Capabilities

PolarSeal® are more than a tape converter, we provide solutions when you need complex and tight tolerance die cuts. We dedicate a project team to focus on you, tailoring strategies to suit your needs. We combine leading adhesive tape manufacturing processes with modern technology to generate cost-effective and high-quality results. With a diverse range of fully validated capabilities, we perform slitting, die cutting, lamination, and printing with precision.

Explore

Flat bed die cutting

Medical die cutting of all types of self-adhesive and non-adhesive products used in numerous medical device applications is a major part of PolarSeal®’s production.

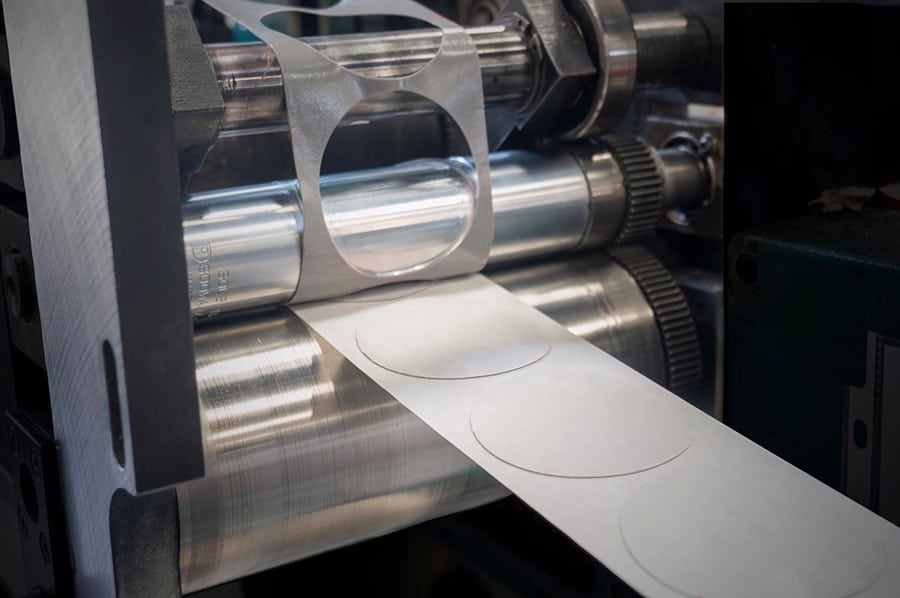

Rotary die cutting

The use of high-speed rotary die cutting equipment fitted with an extensive range of innovative capabilities enables us to configure a vast range of medical devices and possibilities in presentation, style, and format.

Large format die cutting

Our processes are designed to die cut many materials, including tape, adhesive, foam, silicone foam, fabric, film, and more.

Kiss cutting

Die cutting the component without cutting into the liner, so that parts can come off the liner with ease.

Flexographic printing

Roll to roll printing on pressure sensitive label stock, vinyl, cloth, films etc. These can be over-laminated to protect print from the elements or from coming in contact with various solvents which could destroy the ink.

Inkjet product marking

High-resolution printing will allow your parts, products, and packaging imprints to have a superior appearance and legibility.

Wide web lamination

PolarSeal® has extensive facilities to laminate flexible material substrates onto a huge variety of other substrates thus enabling us to supply you with tape or die-cuts constructed to your unique specification.

Multi-zone lamination

Multi-Zone lamination is frequently used to provide areas of non-adhesive material within a construction to aid in the handling and application of your product.

Rewind slitting

Material slitting by rewinding from original cores through a knife system onto core size or type to your specification.

Lathe slitting

All types of self-adhesive and non-adhesive materials can be slit to your specification, whether standard or non-standard widths.

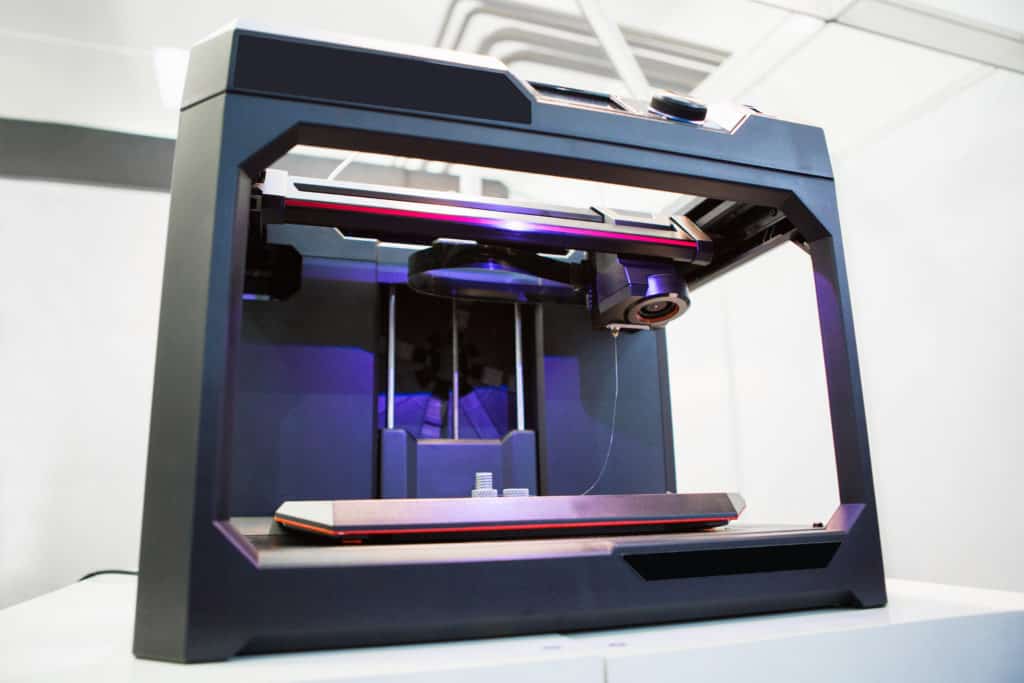

3D printing

Accurate model prototypes are created to scale to provide a precise representation of what the device would look like.

Corona treatment

PolarSeal® can manufacture Corona treated laminated film to your specification on many different types of materials.

Guillotining

Tube filling

PolarSeal® guides customers through the entire product implementation process of fluid-based wet medical devices.

Packing

Our pouch packaging machine seals medical and diagnostic devices into pouches.