Flexographic printing

High quality printing for flexible materials and packaging

As a trusted converter, our printing capabilities ensure the best possible results on a variety of substrates.

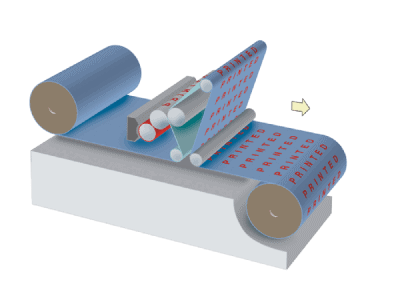

Flexographic printing

Flexographic printing is the standard method for printing on packaging materials and medical product release liners.

Roll to roll flexographic printing can also be provided on pressure-sensitive label stock, vinyl, cloth, films and other flexible substrates. These can then be over-laminated to protect the print from the elements or from coming in contact with various solvents which could destroy the ink.

PRINTING WIDTH UP TO: 350mm

PRINTING WIDTH UP TO: 13.78″

Gallery

PolarSeal® Flexographic Printing

PolarSeal® inline Printing

Frequently Asked QUestions

What is printing?

Through different processes, printing can be applied to the packaging prior to being added to the manufacturing process or printed onto the pouch or packaging to display brand or selected information based on the material being used.

Why use Flexographic Printing?

- Inexpensive

- Laminated for protection

- Non-harmful/Non-toxic inks used

Why use Inkjet Product Marking In-Line?

- Product identification

- Traceability

- Print flexibility

- Reliable and high speed marking

Get in touch

Click below to make an enquiry to discuss your project requirements in more detail.