Large format die cutting

Large scale die cutting

We utilise bespoke cutting methods to produce high-end and high performance components, for all types of self-adhesive and non-adhesive products.

Large format medical die cutting

PolarSeal® has the facility to produce very large-scale die-cuts up to 1600mm x 800mm in size. Large and irregular shaped gaskets or masking products are typical items produced in this way.

MAXIMUM DIE-CUT SIZE: 1600mm x 800mm

Why use PolarSeal® for die cutting?

PolarSeal®’s variety of die cutting techniques and methods can be optimized to suit your application and production volume, resulting in cost savings and improved efficiency.

Our processes are designed to die cut many materials, including tape, adhesive, foam, silicone foam, fabric, film, and more.

- Custom manufacturing processes

- State of the art and technology

- Designated quality and operations team

- 40+ years converting experience

- Excellent service, on time and in full delivery

- Highly collaborative to ensure you get the components you need

Gallery

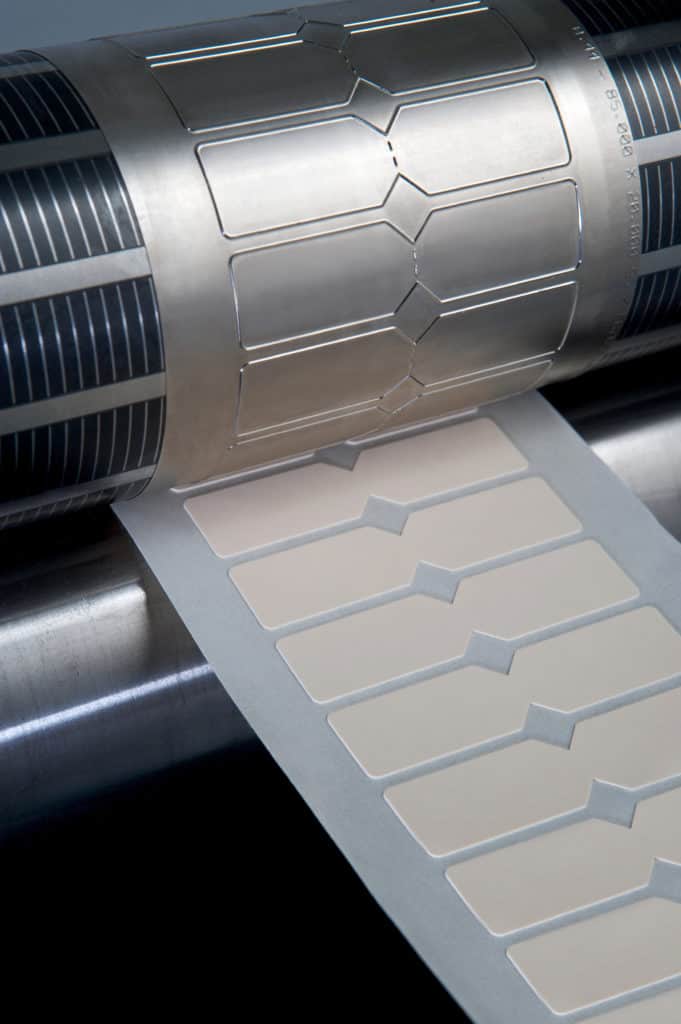

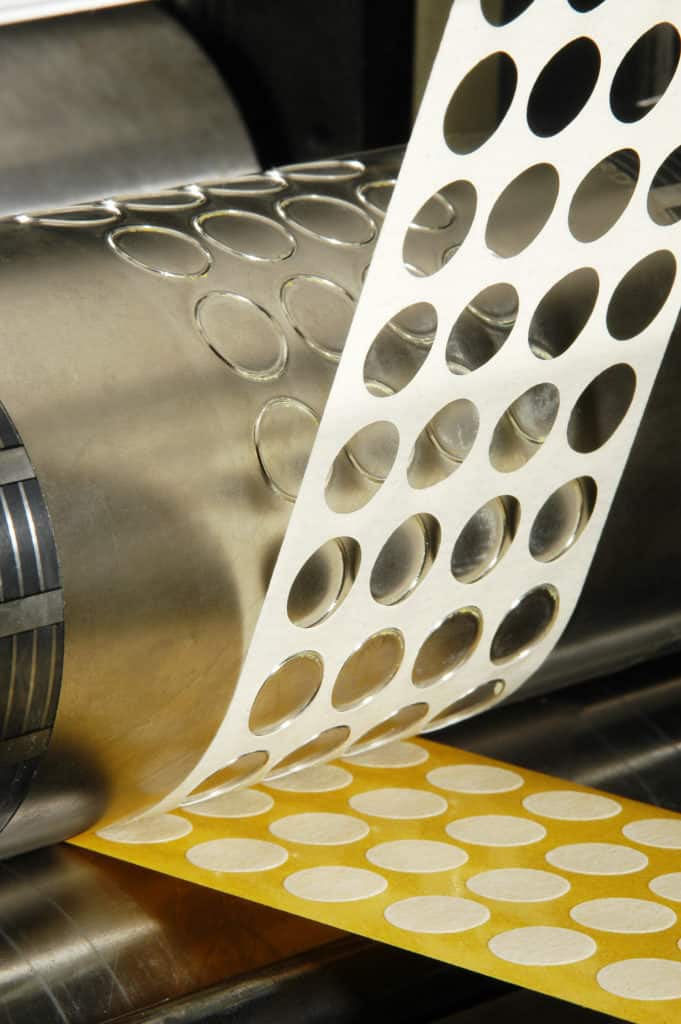

Precision cutting

High volume

Frequently Asked QUestions

What is cutting?

Cutting is converting specified material into precision components. The shape and type of components can be tailored using a variety of cutting techniques.

What are the advantages of die cutting?

- Custom shapes can be created in a simple process quickly and effectively.

- A variety of designs can be cut even through multiple layers.

- High volume can be achieved.

What are the benefits of Rotary Die Cutting?

- High volume production

- High precision and accuracy

- Combining multiple process in the same line such as lamination and printing

What are the benefits of Flatbed Die Cutting?

- Less expensive tooling

- Ability to cut through thicker materials

- Waste reduction

Why choose Large Format Die Cutting?

You will have the ability to cut very large parts that not many machines can convert.