Multi-zone lamination

Laminating self-adhesive materials

PolarSeal® has extensive facilities to laminate flexible material substrates onto a huge variety of other substrates thus enabling us to supply you with tape or die-cuts constructed to your unique specification.

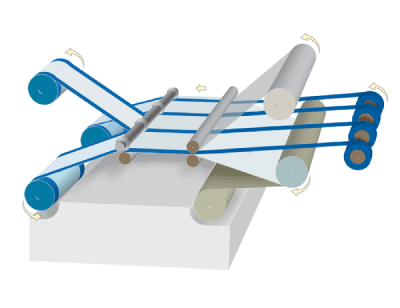

Multi-zone lamination

Multi-Zone lamination is frequently used to provide areas of non-adhesive material within a construction to aid in the handling and application of your product. This process may also be used to provide narrow areas of adhesive for temporary holding or placement of parts.

MAXIMUM LAMINATION WIDTH: 1600mm

MAXIMUM REWIND DIAMETER: 600mm

MAXIMUM LAMINATION WIDTH: 63″

MAXIMUM REWIND DIAMETER: 23.62″

Innovative processes to combine materials

Our in-house laminating capabilities allow us to combine several materials on different presses, with more materials processed and combined on bespoke presses. Our in-house laminating processes include:

- Multi-layer lamination

- Wide web lamination

- Island placement

- Liner substitution

- Zoned adhesive lamination

Frequently Asked QUestions

What is lamination?

Lamination is a process of combining multiple layers of materials.

What are the benefits of material lamination?

- Stable and versatile

- Increased strength with a variety of materials

- Application of a trusted adhesive

- Application of varied material thickness which can be applied to many standard products

- Conducted in a cleanroom environment

What is zoned adhesive lamination?

Get in touch

Click below to make an enquiry to discuss your project requirements in more detail.