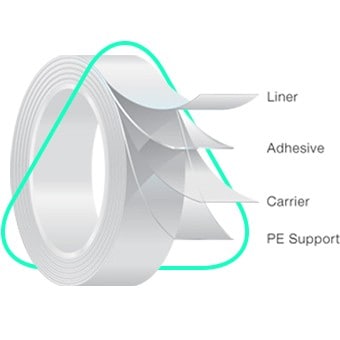

Material selection - converting for ultimate outcomes

Optimal materials for medical devices

Working closely with companies and individuals across all medical sectors, we select the optimal materials for your product functionality.

Selecting medical materials

The material or materials chosen for your medical device needs to flex with the amount of movement in the part of the body it is intended to be applied to, while providing the correct amount of support to the medical adhesive used, to prevent unwanted peeling. Some of the materials we use to manufacture medical devices are below.

Stiff polyester

This type of backing provides excellent resistance to adhesive peeling, however, it is quite inflexible and as such is not recommended for many stick to skin applications but used more typically as strengtheners or shape forming.

Paper

Paper backings are used in several medical devices, from simple dressings to paper tape. Using a paper backing means a tape or dressing can be torn, rather than cut with scissors, making it quicker and easier to apply. Paper backings vary in terms of their resistance to adhesive peeling and body movement.

Woven materials

Woven materials are strong, breathable, and flexible and as such are widely used in medical device manufacture, for products including surgical gowns and masks, drug delivery, wound dressings, and plasters. Woven materials are also used for medical packaging, as their porosity allows gas sterilization.

Woven materials can fray along their edges, meaning they can be deemed unsuitable or inconvenient for longer wear applications or use on areas of the body that experience high degrees of movement. However, where necessary the edges can be bonded using ultrasonic welding to prevent fray.

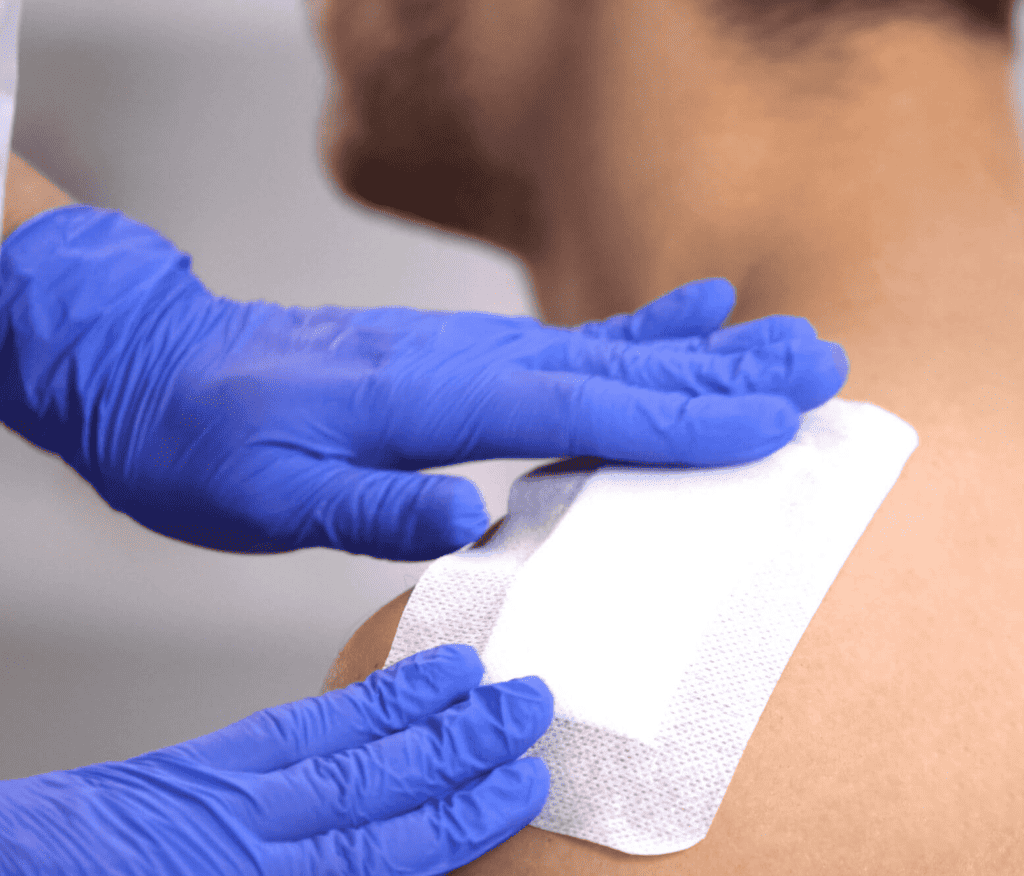

Non-woven materials

Non-woven materials can be manufactured according to a chosen set of criteria, including porosity, fabric weight, thickness, and sterilization capacity. This flexibility and their high resistance to tearing and fraying, natural absorbency, and hypoallergenic nature make these materials a cost-effective choice for single-use, disposal products that don’t require re-cleaning or sterilization such as absorbent pads, drug-delivery devices, and bandages.

Non-woven materials can be manufactured using eco-friendly, natural fibres, which are biodegradable, recyclable, and renewable.

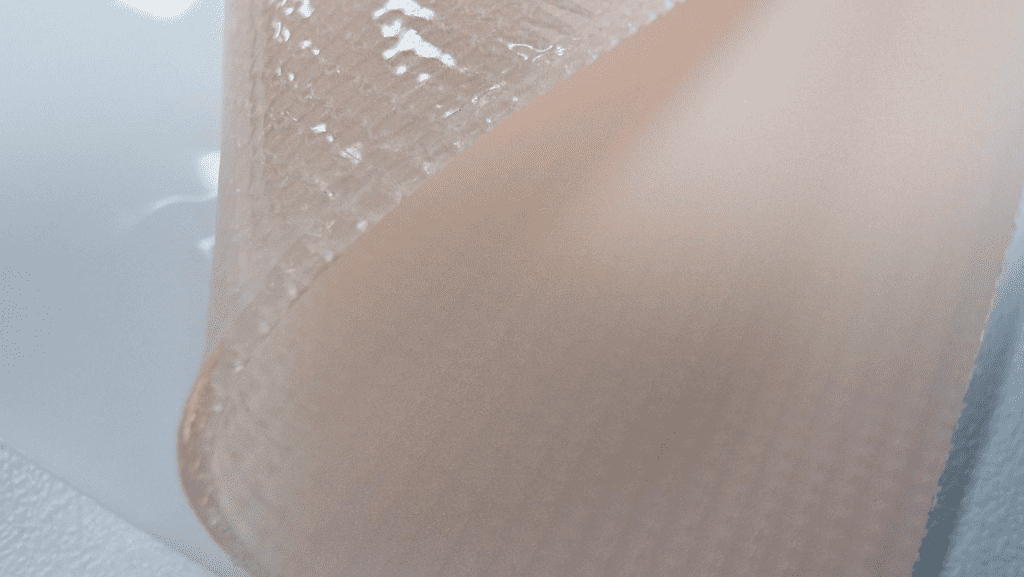

Hydrogels

Hydrogels is a three-dimensional network that can be made from natural or synthetic polymers, and their key feature is their ability to retain large amounts of water while maintaining the structural integrity of the gel.

They can be designed to have different properties, such as porosity and mechanical strength, depending on the intended application, but predominantly are designed to create and maintain a moist environment around the wound, which is considered crucial for the healing process and are utilised for a wide range of medical applications.

Medical foam

Several medical foams are used extensively in medical manufacturing for many solutions, including wound care products and consumer healthcare, as this material is typically lightweight and durable. Furthermore, it can be impregnated with many solutions, such as fungicidal and bacterial additives to create a product with accelerated healing properties.

The foam also has vibration-dampening and insulating properties that make it highly suited to medical packaging solutions.

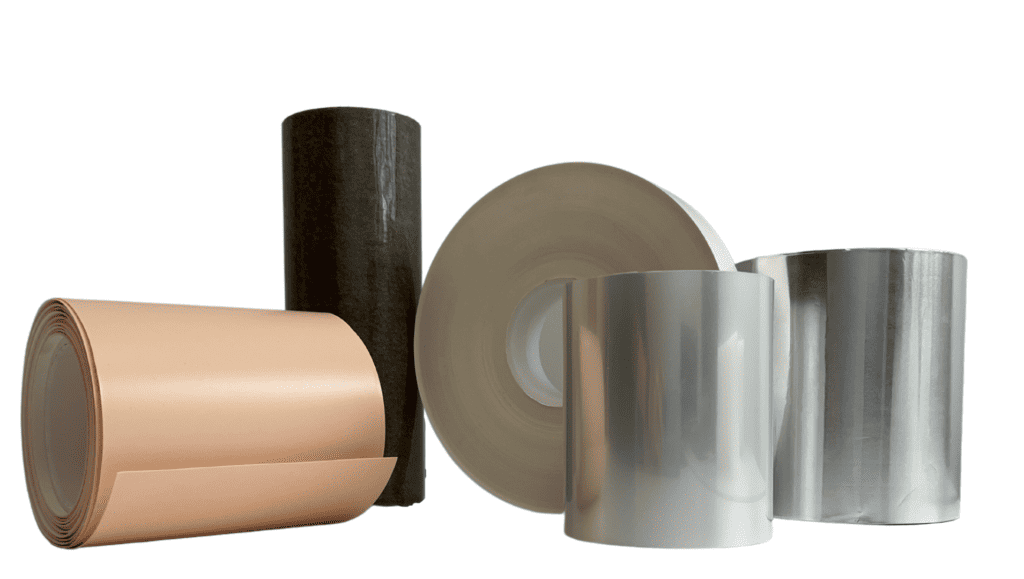

Medical films

Medical grade films can be manufactured to exacting specifications concerning antimicrobial properties, breathability, bio-compatibility, and heat stability.

Due to this flexibility, films have a number of purposes within the medical industry, they can be used in the manufacture of wound care products and their release films, surgical gowns, medical fluid bags, transdermal patches, and medical packaging.

Films can also be laminated onto synthetic non-wovens, wovens, or any textiles and used in single-layer or multi-layer constructions.

Gallery

3M materials