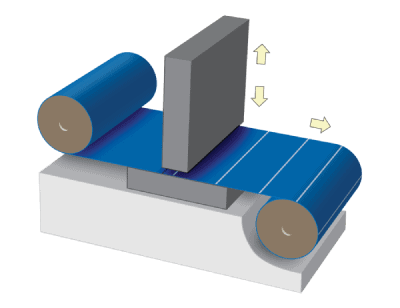

Flat bed die cutting

Precision die cutting

We utilise bespoke cutting methods to produce high-end and high performance components, for all types of self-adhesive and non-adhesive products.

Flat bed medical die cutting

Medical die cutting of all types of self-adhesive and non-adhesive products used in numerous medical device applications is a major part of PolarSeal®’s production. To produce a die-cut, certain parameters need to be assessed such as material type, tolerance, volume, and final presentation required. Once these have been assessed and the feasibility of producing the required die-cut ascertained, the machine and tool type is then selected. There are four main tooling options: steel rule, two-part die set, rotary die, or rotary flexi-die with cutting tolerance down to ±0.003mm achievable, subject to the type of material being cut. Presentation is a very important item to be addressed as the correct presentation relative to the product and your manufacturing methods will result in cost-effective, time-saving processes. With over 30 years of experience, PolarSeal® will guide you in the choice of individual pieces, roll form, dry edge, split liner, sprocket holed, or other configuration for an efficient engineered part.

MAXIMUM DIE-CUT SIZE: 250mm x 200mm

Why use PolarSeal® for die cutting?

PolarSeal®’s variety of die cutting techniques and methods can be optimized to suit your application and production volume, resulting in cost savings and improved efficiency.

Our processes are designed to die cut many materials, including tape, adhesive, foam, silicone foam, fabric, film, and more.

- Custom manufacturing processes

- State of the art and technology

- Designated quality and operations team

- 40+ years converting experience

- Excellent service, on time and in full delivery

- Highly collaborative to ensure you get the components you need

Gallery

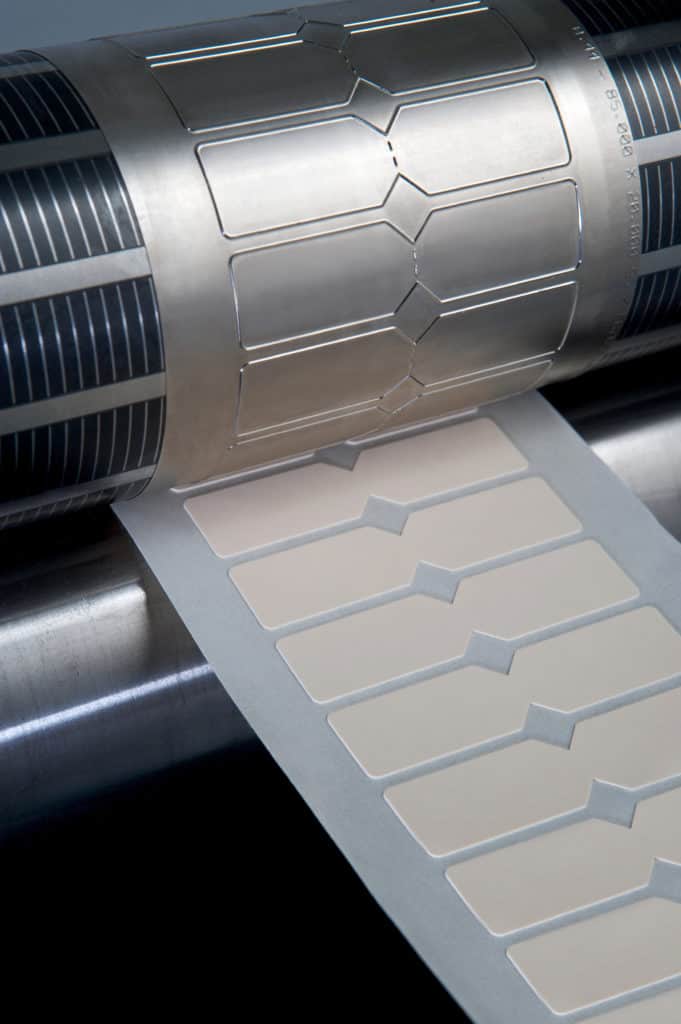

Precision cutting

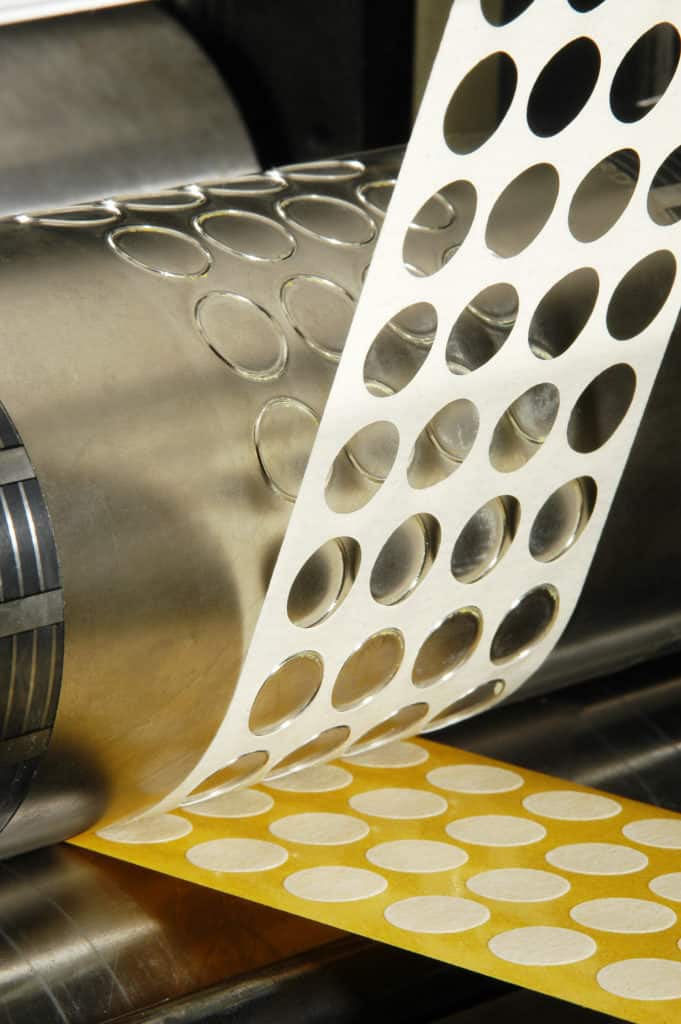

High volume

Frequently Asked QUestions

What is cutting?

Cutting is converting specified material into precision components. The shape and type of components can be tailored using a variety of cutting techniques.

What are the advantages of die cutting?

- Custom shapes can be created in a simple process quickly and effectively.

- A variety of designs can be cut even through multiple layers.

- High volume can be achieved.

What are the benefits of Rotary Die Cutting?

- High volume production

- High precision and accuracy

- Combining multiple process in the same line such as lamination and printing

What are the benefits of Flatbed Die Cutting?

- Less expensive tooling

- Ability to cut through thicker materials

- Waste reduction

Why choose Large Format Die Cutting?

You will have the ability to cut very large parts that not many machines can convert.