Guillotining

Medical material guillotining

PolarSeal® possess the guillotining capabilities for various laminating and sheeting to custom sizes, tailoring the materials to your direct specifications, delivering efficiency, and saving our clients costs. Our state-of-the-art machinery has the capability to combine multiple materials to convert and fit the specification you require, which ensures we remain as a trusted medical device manufacturer.

Guillotining for laminating and sheeting to custom sizes

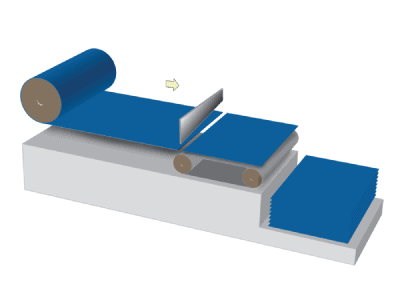

The guillotine is a process that is roll-fed and can conduct lamination and sheeting in one step. It is also commonly used to apply different adhesive types to non-adhesive substrates and sheet to squares and rectangles, to aid the final application of the product.

Additionally, we can laminate zones of material, in specific locations across the width and can apply various application aids, such as overlapped carrier liners, to already adhesive materials while sheeting. This process is most commonly used for the manufacture of incision films where handlebars can be added, support films removed and the film is guillotined into the final dressing sheet size before being rolled and packed.

MAXIMUM SHEET WIDTH: 1100mm

MAXIMUM SHEET LENGTH: 1600mm

WITH IN-LINE LAMINATION FACILITY

Frequently Asked QUestions

What is Guillotining?

Guillotining is a role fed laminating and sheeting machine. This is where an adhesive or non-adhesive solution is added to aid in the application to a material.

What are the advantages of Guillotining?

- Ability to combine multiple materials to fit your requirements

- Material rolls converted to sheets for direct use

- Material rolls converted to sheets for additional conversion