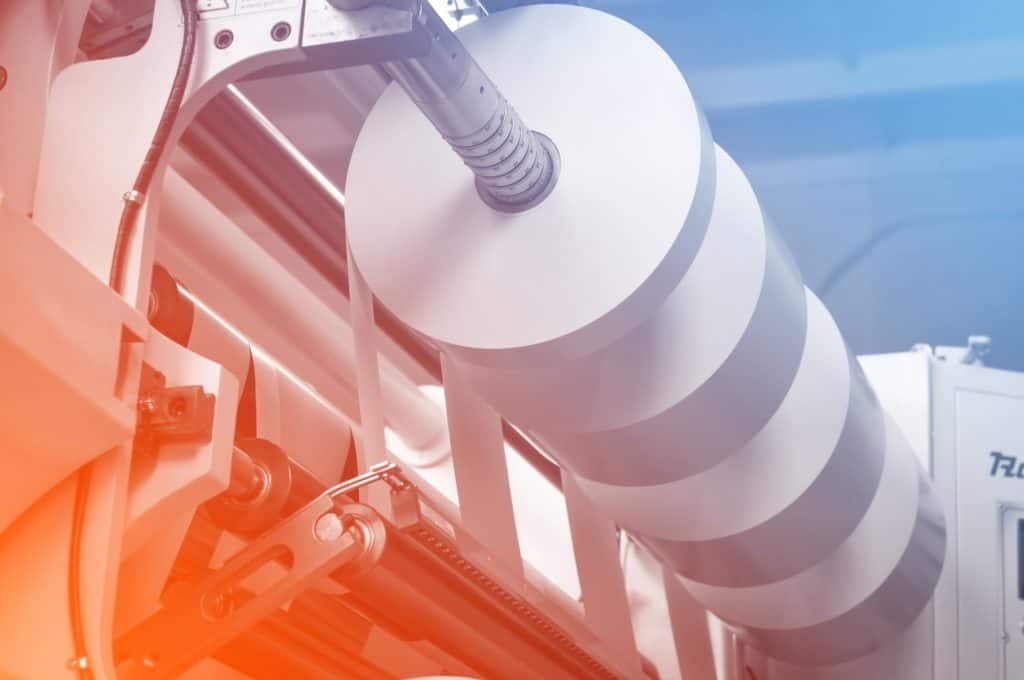

Rewind slitting

Converting expectations met with precision slitting

Slitting of adhesive and non-adhesive coated materials to custom widths.

Rewind slitting

Material slitting by rewinding from original cores through a knife system onto core size or type to your specification. This method enables any length to be rewound onto any individual core.

UNWIND: MAXIMUM LOG WIDTH: 1600mm

MAXIMUM LOG DIAMETER: 1000mm

REWIND: SLIT WIDTHS DOWN TO: 25mm

PolarSeal® slitting materials

PolarSeal® performs slitting for the following materials:

- Adhesive

- Tape

- Foam

- Non-wovens

- Foil

- Film and Liner

- Medical grade materials

Do you require a non-standard roll width?

Contact a converting expert today for a custom solution to meet your exact roll width requirements.

Frequently Asked QUestions

What is Slitting?

Slitting is cutting large rolls (master roll) of material in narrower rolls.

What are the benefits of Lathe Slitting?

- Bespoke sizing can improve your operational efficiency

- Sizing tailored to your needs can reduce waste

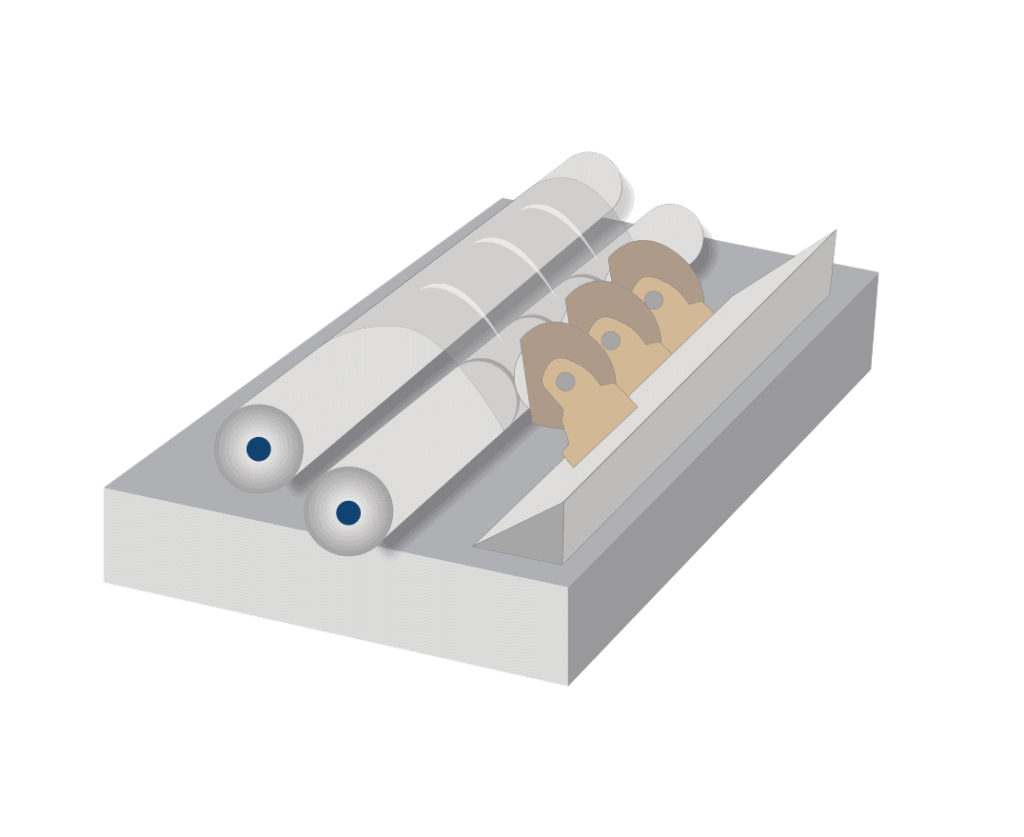

What are the benefits of Rewind Slitting?

- Parts can be customized

- Reduction in your production process

- Bulk buying of materials can reduce cost

What is the minimum slit width?

- Our minimum slit width is 3mm. Wider slit widths, the material becomes more stable.

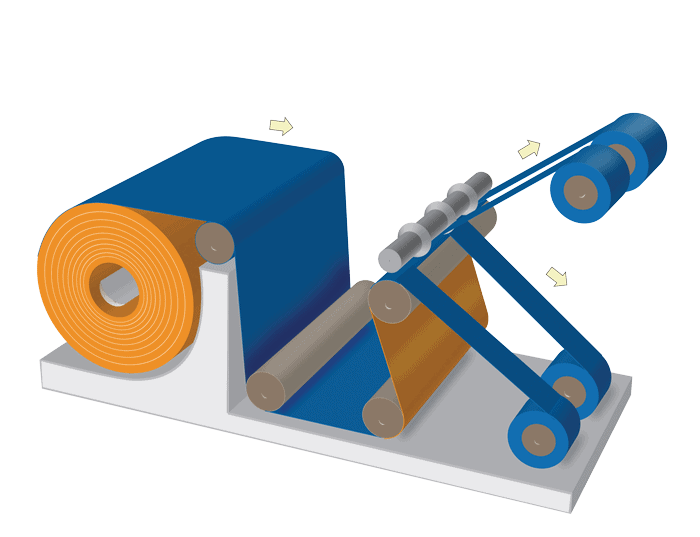

What type of slitting is best for the material?

- Shear: A male and female rotary knife

- Razor: A razor blade that cuts “in-air” or “in-groove”

- Score/Crush: A rotary blade pressed into a hardened anvil roller

Get in touch

Send us an email to discuss your project requirements in more detail or book a 1-on-1 video call with a member of the team on a day and time that suits you best using the calendar booking system.