Kiss cutting

Die cutting laminated materials

Optimised die cutting techniques to suit your application and production volume with cost saving solutions.

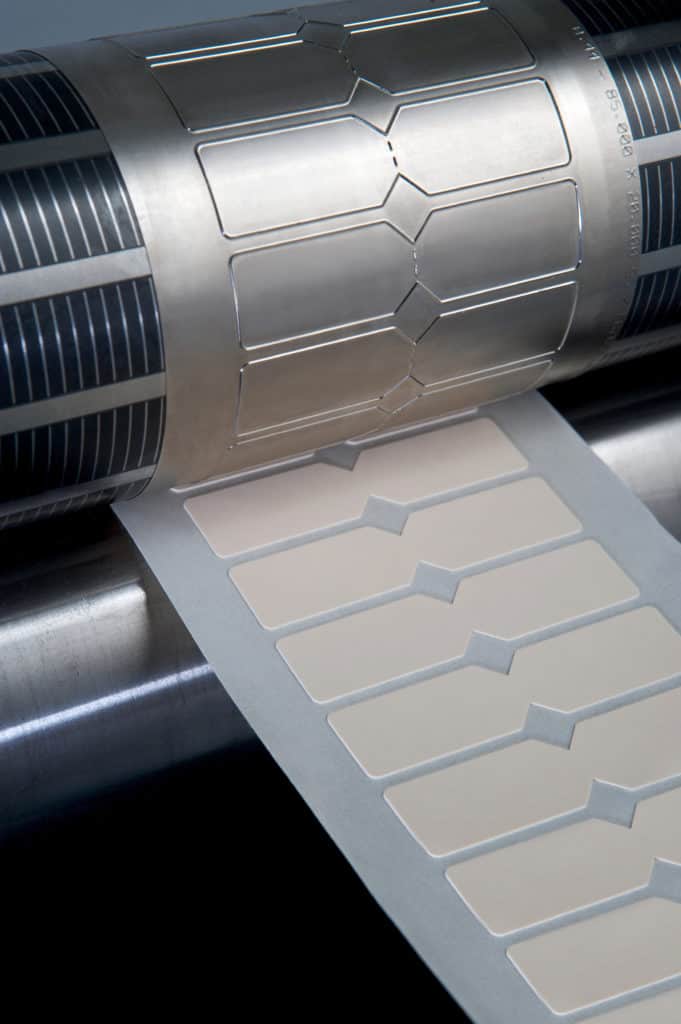

Kiss cutting

PolarSeal® take use in-house capabilities to perform precision kiss cutting, die cutting the component without cutting into the liner, so that parts can come off the liner with ease. The waste material is removed, wound onto a core and provided in role format allowing you to handle each component more easily.

PolarSeal® provides kiss cutting for rotary and flatbed processes with the ability to die cut many materials including:

- Foams

- Fabrics

- Film

- Tape

- Adhesive

Why use PolarSeal® for die cutting?

PolarSeal®’s variety of die cutting techniques and methods can be optimized to suit your application and production volume, resulting in cost savings and improved efficiency.

Our processes are designed to die cut many materials, including tape, adhesive, foam, silicone foam, fabric, film, and more.

- Custom manufacturing processes

- State of the art and technology

- Designated quality and operations team

- 40+ years converting experience

- Excellent service, on time and in full delivery

- Highly collaborative to ensure you get the components you need

Gallery

Precision cutting

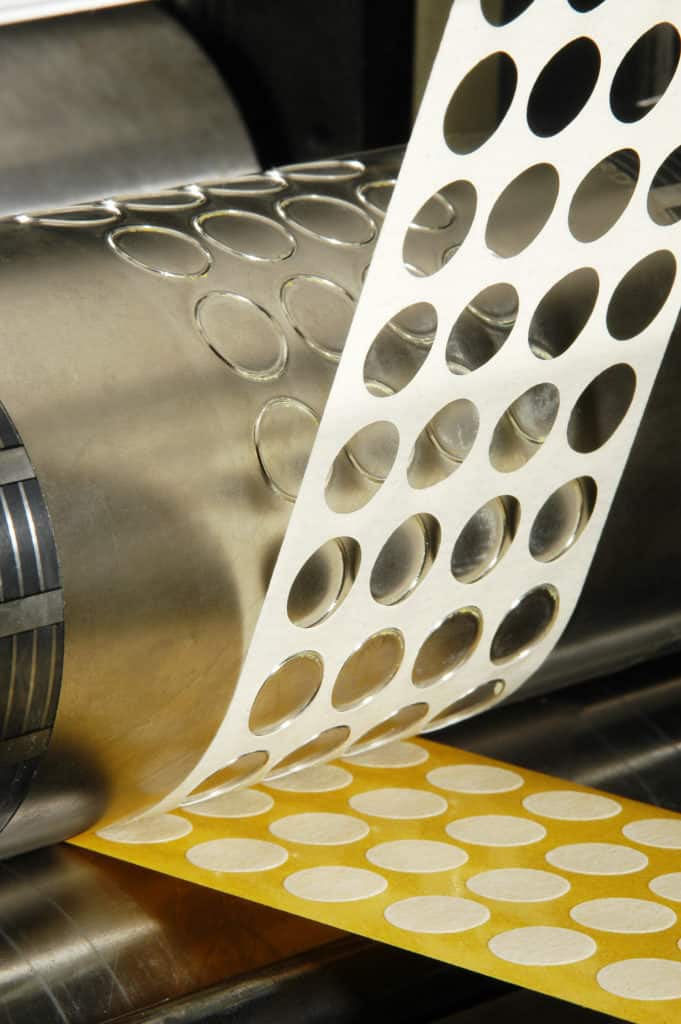

High volume

Frequently Asked QUestions

What is cutting?

Cutting is converting specified material into precision components. The shape and type of components can be tailored using a variety of cutting techniques.

What are the advantages of die cutting?

- Custom shapes can be created in a simple process quickly and effectively.

- A variety of designs can be cut even through multiple layers.

- High volume can be achieved.

What are the benefits of Rotary Die Cutting?

- High volume production

- High precision and accuracy

- Combining multiple process in the same line such as lamination and printing

What are the benefits of Flatbed Die Cutting?

- Less expensive tooling

- Ability to cut through thicker materials

- Waste reduction

Why choose Large Format Die Cutting?

You will have the ability to cut very large parts that not many machines can convert.

Get in touch

Click below to make an enquiry to discuss your project requirements in more detail.