Since the birth of PolarSeal in 1981, we have continuously expanded our premises and services to accommodate for our customer with a goal of becoming the full end-to-end service provider within contract medical manufacturing and converting. Part of our expansion has seen the acquisition of new facilities and additional warehousing; this addition allows us to add a unique service such as Outsourced Operations.

Coupling decades of experience and available space provides a unique solution for our customers enabling them to utilize this offering. The passionate PolarSeal team will bring your machine / production line in-house, manage the process, and manufacture with our experienced operators, delivering finished products to your desired location.

Outsourcing process includes: |

|---|

1. Your machinery hosted within PolarSeal facilities |

2. Installed and run in or out of our ISO 7 Class 10,000 Cleanrooms |

3. Highly experienced operators handle the manufacturing process |

4. Quality management ensures process and parts are met in line with Quality regulations |

5. Your finished products are then pouched (optional) and packed |

6. PolarSeal uses strong distribution network to handle your logistics |

An example of where this has been successful for one of our customers:

We have an open-door policy, so following installation you can visit your line and see the progress as much as you like. Our dedicated projects and operations teams will work tirelessly to ensure we meet your volume expectations. You will also have frequent communications with our team during the installation stage as well as during manufacture. Our new digital portal will provide transparency of every stage and send you a notification upon completion of each run and further updates once your order is packed and dispatched for delivery.

How can utilizing this service be of benefit to you, your business and your final product? |

|---|

1. Shift focus to other matters of business |

2. Reduce in-house stressors |

3. Cost effective solution, allowing you to use your space in other ways or simply add another line with us without having to expand your sites |

4. Visit your production line anytime |

5. Free up internal resource and space |

6. Experienced in-house team to produce quality parts and products |

7. Passionate team to handle the entire process including installation, material sourcing and distribution |

8. Confidence in knowing your products and or components are being produced at the highest quality with fully accredited flexible material converters |

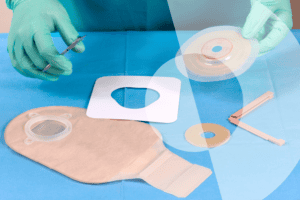

This solution accommodates all customers from startups who don’t have the space, to large medical manufacturers looking to add additional lines or remove lines from their current facilities. Our team welcomes you to meet us at our facilities so you can see the premises and capabilities for yourself.

Read More from PolarSeal

When should you outsource your tube filling and liquid formulation?

The process of formulating a fluid-based medical device typically involves several key steps, we review the process from concept to market and answer the questions

Are you dealing with multiple vendors for one project?

Medical device manufacturing is a complex and highly regulated industry that requires collaboration and coordination between multiple stakeholders, including manufacturers, converters, suppliers, and regulatory agencies

Outsourced Operations and the Future of Healthcare

PolarSeal offers outsourced operations: they have the ability to bring machinery in-house, they then set it up in one of their production areas or a