Introduction

Advanced wound care has seen tremendous progress in recent years, with the development of super-absorbent wound dressings that can effectively manage exudate and promote healing. But have you ever wondered how these dressings achieve their remarkable absorbency?

For a wound dressing to be super-absorbent, it needs a moisture-wicking material that can effectively soak up and trap the wound exudate. Materials in this class include hydrogels, super-absorbent polymers, foams and fibres. These are polymeric materials that can absorb and retain vast amounts of water or aqueous fluids while maintaining their structural integrity.

The Science of Hydrogels

Hydrogels are composed of cross-linked polymer chains that form a three-dimensional network. These polymer chains are hydrophilic, meaning they have an affinity for water molecules. When hydrogels come into contact with aqueous solutions like wound exudate, the water molecules are attracted to the polymer chains and become entrapped within the hydrogel’s structure.

The ability of hydrogels to absorb and retain fluids is influenced by several factors, including the type of polymer used, the degree of cross-linking, and the presence of specific functional groups. By carefully controlling these factors, manufacturers can engineer hydrogels with varying degrees of absorbency and swelling capacity.

Super-Absorbent Polymers (SAPs)

A particular class of hydrogels known as super-absorbent polymers (SAPs) has revolutionized the wound care industry. SAPs are capable of absorbing and retaining several times their weight in liquids, making them ideal for managing heavily exuding wounds.

One of the most commonly used SAPs in wound dressings is sodium polyacrylate. This polymer contains carboxyl groups that dissociate in the presence of wound exudate, creating negatively charged sites along the polymer chains. These charged sites attract and bind to the positively charged ions in the wound fluid, facilitating the absorption and retention of exudate.

In simple terms, sodium polyacrylate acts like a sponge, soaking up and trapping wound fluid, preventing any leakage or mess.

Advanced Wound Dressing Design

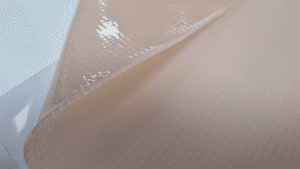

The manufacturing process of super-absorbent wound dressings involves carefully integrating the hydrogel or sodium polyacrylate (SAP) material into the absorbent core layer. This core layer is strategically positioned beneath the outer semi-permeable film or fabric, which serves as a barrier against bacterial penetration while allowing air and moisture vapor transmission.

The incorporation of the hydrogel or SAP into the core is a critical step, as these highly absorbent polymers are responsible for rapidly drawing in and retaining exudate from the wound site. At PolarSeal, we employ precise techniques to evenly distribute and secure the hydrogel or SAP within the core layer, ensuring optimal absorbency and fluid management capabilities.

In some dressing designs, additional layers may be incorporated during the manufacturing process. These can include non-adhering wound contact layers to prevent dressing adherence to the wound bed, or vertical wicking layers that promote even distribution of exudate across the absorbent core.

Benefits of Super-Absorbent Dressings

The ability of super-absorbent dressings to manage wound exudate effectively offers several benefits for wound healing:

- Reduced risk of maceration: By effectively absorbing and retaining exudate, these dressings prevent the harmful effects of excess moisture on the peri-wound skin, reducing the risk of maceration and further tissue damage.

- Improved patient comfort: Highly absorbent dressings can help minimize the need for frequent dressing changes, improving patient comfort and reducing the risk of wound disturbance.

- Promotion of a moist wound environment: While effectively managing excess exudate, super-absorbent dressings maintain a balanced moist environment at the wound bed, which is conducive to healing.

- Reduced risk of infection: By effectively managing exudate and maintaining a moist wound environment, these dressings can help reduce the risk of wound infection and promote healing.

PolarSeal's Expertise in Advanced Wound Care Manufacturing

As a 100% medically focused converter, PolarSeal are the experts in the manufacture of multi-layer wound dressings, offering comprehensive end-to-end solutions for medical device and wound care brands. Our unmatched expertise in advanced wound care allows us to handle the entire manufacturing process, from material selection and regulatory considerations to sterilization, packaging and pouching.

RELATED CONTENT

Four Innovations Revolutionising Wound Care

In this blog, we look at the latest innovations in wound care focusing on the benefits to consumers and important manufacturing considerations to be aware of.

5 Key Insights into Wound Care Device Manufacturing

Wound care devices play a crucial role in the healthcare industry, aiding in the treatment and healing of injuries. As technology continues to advance, so

Hydrogel Wound Care Manufacturing

Key considerations When manufacturing a hydrogel dressing, it is essential to consider various factors to ensure the production of a high-quality product that meets safety