On a daily basis, the medical community has to deal with liquids or wet biomedical products. From tubes of antiseptic to silicone gel adhesives, the practical use of active-ingredient liquid or semi-liquid products are a mainstay in the medical industry. Patients rely on these products every single day – from run-of-the-mill moisturiser to life-saving topical medicines. The importance of having a manufacturer who understands the high stakes of these products and the process they go through to be produced cannot be understated.

Machine-based, semi-automatic tube filling is popular right now – and it’s not difficult to see why. Tube filling has clear benefits. The automated process means reduced labour costs (as the machines are programmed to do this process at speed) as well as fewer wasted products (tubes allow product to be used right up to the very last drop), allowing for higher profit turnover and even a greener product. However, these benefits are dependent on knowing your way around tube filling.

This is where PolarSeal comes in – we are a company that understands the practical needs of products that deal with liquid as we have been industry leaders in working with materials and adhesives in the medical community for over four decades. In that time, we have learned to understand the flexibility and durability of certain materials, while noting the problems with others – in short, we know what we are doing.

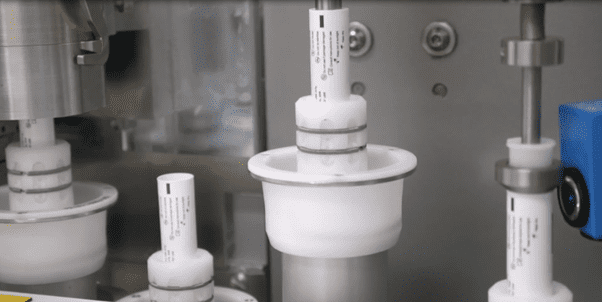

Our experience in dealing with wet medical devices and products has allowed us to develop a tube filling system that is high-quality, adaptable, and fast – a production line that is able to swiftly manufacture products without sacrificing quality.

PolarSeal’s production capabilities are simple – we make use of a semi-automatic tube filling machine. This machine is adaptable and can be altered to fit the specifications of whatever liquid and container you wish you pair together – from gels, liquids, ointments, pastes, and creams into tubes, bottles, vials, or jars. This allows for a greater focus on what container best fits your liquid product – does it need to be stored in glass? How malleable must the tubes be? We can create an R&D prototype that will help determine the answers.

Since we are not simply a tube-filling company – same as we are not simply a surgical films company, we can also assist with the formulation and product development from start to finish, including packaging, labelling, distribution, and sterilisation. Tube filling, far from being a static practice, can be as dynamic as your imagination.

If you’ve been considering a change from cost-inducing hand-filled tubes and medical products, it may be time to consider the switch to a machine-based tube filling system. The positives are clear, and it may be difficult to remain competitive in this environment without making use of machinery and a company with the aptitude of PolarSeal when it comes to tube filling.

To get a fuller understanding of PolarSeal’s capabilities, contact us today. We would love to be able to discuss your project and how we can potentially use our knowledge to make it into an incredible product.