The Hurdle

Within a heavily regulated market, development of a new or existing medical device and taking it to market requires intense and closely monitored project management. Furthermore, time and monetary investment place strain on startups as well as large med-dev companies. Ensuring successful market entry, many departments and factors are involved and needed, including:

- Quality Assurance

- Project Management

- Product Development

- Marketing and go-to-market strategies

- Sterilization

- Converting and manufacturing

- Product testing

- Operations and more…

This required resource from all departments places strain on department management attempting to meet tight deadlines. With internal stressors, is in-house manufacturing the solution or is outsourcing the project a more cost effective and time friendly approach?

Enablement

As a leading and 100% medically focused flexible material converter and adhesives specialist, PolarSeal offer a circular and continuous solution for the development of new or existing medical devices. Our advanced in-house converting capabilities and designated project management teams allow us to serve the global medical market including Wearable Medical Devices; Advanced Wound Care; Consumer Health Care; Tube/vile filling; electro-medical; incise films; Diagnostics; Biomedical & Life Sciences and more. Utilizing die cutting, material slitting, printing, pouching, and lamination, we can combine the ‘application perfect’ material and adhesive for optimum performance.

PolarSeal’s strong partnerships with medical material suppliers like 3M, allows us to source materials such as hydrocolloids, woven and non-wovens, through to medical foam and hydrophilic materials. Using our in-house product development, quality assurance and management teams, we collaborate with you closely to give you the best and most desired outcome.

The Process

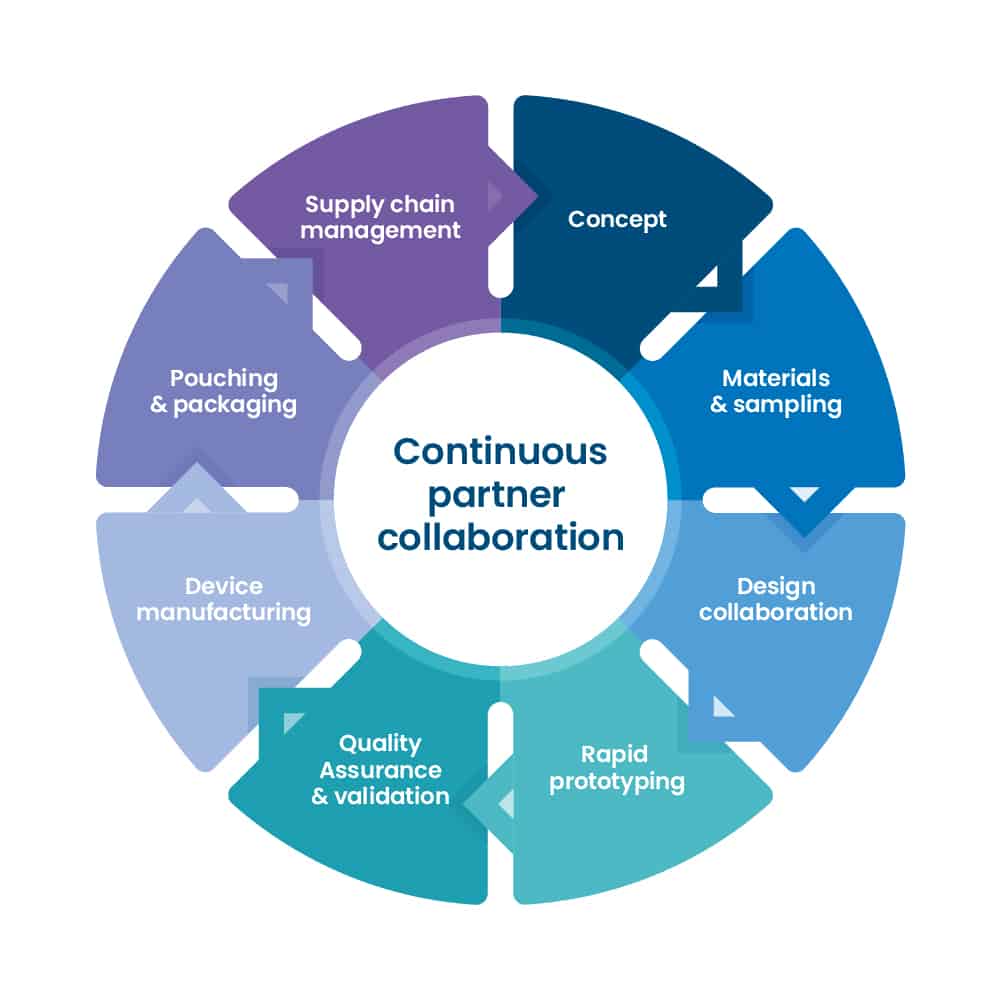

PolarSeal’s continuous and circular solution empowers medical devices companies of any size to enter the process at any point. Be it right from when the idea is born into a concept to sourcing materials, rapid prototyping, contract manufacturing and supply chain management, PolarSeal’s experienced and trained teams empower companies with the flexibility and trust in knowing their project is in good hands. With relentless clear and concise communication, you are fully aware of what stage your project is in and when you expect delivery.

As logistics is handled, you can yet again focus on your next project which PolarSeal will be there to assist starting again from concept or whichever stage in the process needs assistance.

We are your converting experts and here to provide service and cost-effective solutions your business deserves.

If you have a challenge you think we can provide a solution for, please don’t hesitate to contact us.