How do you make the best use of the medical applications available to you for medical manufacture and how can these services be applied? What capabilities do these services enable? As a result of knowing these answers, how can you practically capitalise on your medical manufacturer’s capabilities?

To give you a potent example of applications, let’s take a look at what kind of medical applications a successful and capable medical manufacturer would offer.

Wound Care

Everything from the humblest bandage to surgical-grade anti-microbial wound dressings – this is pretty much a staple for any medical manufacturer. Wound care is a cornerstone of the medical manufacturing industry as any product used in wound care needs to be both sterile and plentiful. However, as you know, simply creating a wound dressing takes more than gauze and tape. This is why applying services to designing, prototyping, and testing different materials is essential to producing an excellent product.

Fixation Devices

The human body can be notoriously difficult… which is why you’re reading this book. Sometimes, it needs a little help with bringing things in and taking things out – everything from catheters to oxygen lines to endotracheal tubulation is a ‘fixation device’. This is why you need to make certain that fixation devices are perfectly created, it’s critical as they represent the bridge between the inner body and the outer world.

Electro-Medical Devices

As technology evolves, electrical equipment and the human body are becoming more and more used to each other. These kinds of devices are often used in monitoring equipment like brain electrodes or skin patches with small electronic components to measure heart-rate, breathing, temperature, or pulse-oximetry. These kinds of devices benefit from R&D and prototyping and will potentially result in a longer ‘engagement’ period before it is produced in mass quantities.

Continence & Ostomy Components

Ostomy bags and components are going through a bit of a social revolution with more awareness being brought to what was traditionally seen as a shameful part of a person’s health. This awareness is also in line with the growth in the ostomy industry, with a growing global market of around USD 2.8 billion. Like fixation devices, these devices are bridges between the inner and outer, with these devices in particular requiring long-term durability.

Surgical Films

Few components are more critical than those that are used when performing actual surgery, so surgical films, like incision films, fixation tapes, and bordering tapes are keys to minimising the chance of infections. Having a cleanroom up to standard will be massively important to make sure that everything is antibacterial and skin-friendly.

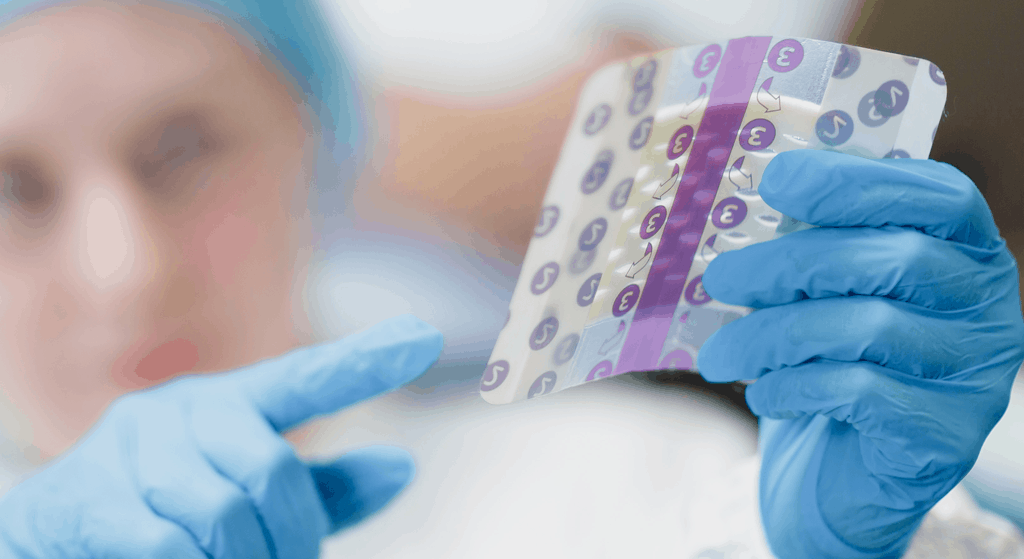

Diagnostic Products

These kinds of devices are membranous strips to be used in testing for various conditions, ailments, and infections. These are often produced in mass quantities as they are widely disseminated and used daily.

Consumer Healthcare

These kinds of medical devices are the drug store/chemist variety – things you can find on the rack of your local pharmacist. However, just because these blister plasters, cosmetic patches, or simple bandages are used for popular consumption, as opposed to being used in critical life-saving procedures, doesn’t mean that your medical manufacturer will cut corners.

Wearable Technology

When most people think of ‘medical devices’, their minds will probably go to wearable technology. Things like pacemakers, diabetes monitors, and biosensors. These will usually have an emphasis on how to balance weight with breathable adhesives or fabrics that stick to the skin.

Personal Protective Equipment

In this era, even a specialising medical manufacturer has probably reserved some portion of their manpower and equipment to produce PPE. The demand from pretty much the entire global population for more plentiful and higher-quality PPE has informed the supply that most medical manufacturers are outputting right now.

Liquids

Finally, there is likely an entire chunk of your medical manufacturer that is dedicated to wet products – things like gels, pastes, creams, saline, and other liquid products to be used in medical procedures.

For the previous blog in this mini-series, which looks into which medical manufacturing services are right for you, please CLICK HERE.

To see our next blog in this mini-series, FOLLOW OUR PAGE ON LINKEDIN and look out for the link!